It takes specialized companies up to two weeks to assemble prostheses equipped with complex mechanics and electronic control systems, explained Denis Khashev, one of the developers, student at the Robotics and Mechatronics Department of the DSTU's Automation, Mechatronics and Control Faculty. The time it takes depends on the functionality of the assembled prosthetic hand and the necessity to adapt it to the individual characteristics of the person it is intended for.

READ MORE: Russian Scientists Know How to Slow Down Extinction of Muksun

"Our system enables the prosthesis to be designed in the shortest possible time so that it matches the patient's other hand perfectly," the developer said. "It takes about three hours to adjust the prosthesis to a specific patient, and just two to three days to fully assemble it."

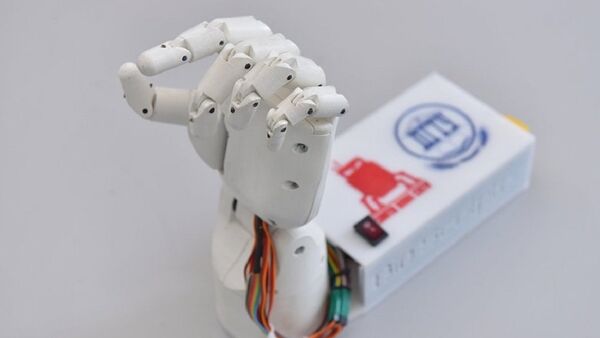

The prosthesis developed at the Rostov Region's flagship university is also multifunctional: every finger has its own lever mechanism, while the hand can hold objects of various shapes and make all kinds of gestures.

Creating the prostheses and developing the system designed to be able to fit the individual characteristics of patients took about six months. Another developer, Yulia Mikhailina, a student at the Tool Engineering and Biomedical Engineering Department of the DSTU's Tool Engineering and Technical Regulation Faculty, states that in order to develop the prosthesis, students carried out research on the parameters of the human hand. "We traced the hands of 50 young people, aged between 18 and 25, and marked their phalanges to calculate the average value of every parameter," she said.

"This research is aimed at speeding up the process of developing prostheses and ensuring its better adjustment to the patients' individual anthropometric characteristics," said Alexei Lysenko, head of research and assistant professor at the Robotics and Mechatronics Department, adding that the students' work facilitates the quick and efficient creation of a 3D model and a fully personalized prosthesis.

The students' innovation can already be implemented in the production process, Lysenko said. During the course of this year, the students are planning to perfect the prosthesis by introducing a control system based on electromyography and encephalography technologies, which allow brain signals to be read.