According to university experts, the technology will be used for medical purposes. It will allow the coating to be applied to implants and will protect against inflammation, prevent rejection of implants and shorten the postoperative period.

"Inflammatory response is among the key problems that impede the rapid integration of an implant with natural tissues. The colonization of bacteria and fungi results in the formation of a highly adhesive biofilm on the implant's surface, which is difficult to remove by traditional means of medical therapy. Applying an antibacterial coating on implants is an efficient way to resolve this problem," Professor Yevgeny Levashov, a leader of the research team, head of the NUST MISiS Powder Metallurgy and Functional Coatings Department and head of the Scientific-Educational Center of SHS, told RIA Novosti.

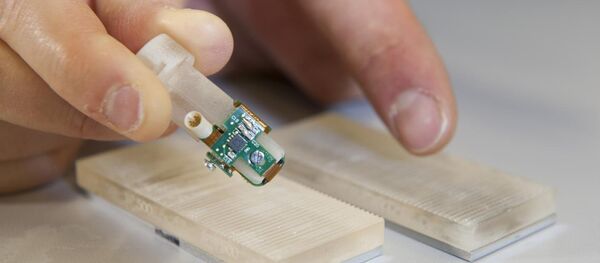

The new technology will be used to process implants made of various alloys for medical purposes. For example, it could be used to produce titanium implants, designed to replace the affected parts of bone tissue: orthopedic and dental implants, implants for maxillofacial and spinal surgery, artificial joints, cribs, etc. These are the implants that are exposed to intense mechanical loads.

"The bioactive third-generation coating contains elements that kill harmful bacteria. The coating, applied to an implant, protects against an inflammatory response, prevents rejection of implants and therefore reduces the postoperative period by 50 —100 percent," Yevgeny Levashov said.

According to the scientist, the new antibacterial coating is equal or even surpasses its global equivalents. The new technology has been three years in the making. Researches have already patented their development in Russia and in the Patent Cooperation Treaty international system. However, clinical trials that still remain ahead will directly depend on funding.