Researchers from the Moscow-based National Research Nuclear University MEPhI have conducted a study on the use of isotopically modified molybdenum as an alternative to zirconium alloys from which nuclear fuel-element casings are created.

Today, zirconium alloys are the main material used in the fuel-element casings containing uranium oxide pellets. The material features high erosion and corrosion resistance in water, along with a low thermal neutron capture cross-section (the property characterizing the probability of chemical interaction between neutron particles and the atom nucleus).

However, zirconium alloys are also known to have several drawbacks, including the generation of heat in water and the production of hydrogen, which accelerates the degradation of the fuel-element casings. This occurs during zirconium-steam reactions, which take place when temperatures reach above 700 degrees Celsius, which can be very dangerous in emergency situations at water-cooled nuclear power stations. A zirconium-steam reaction is believed to have been one of the causes of the Fukushima Daiichi nuclear disaster in 2011.

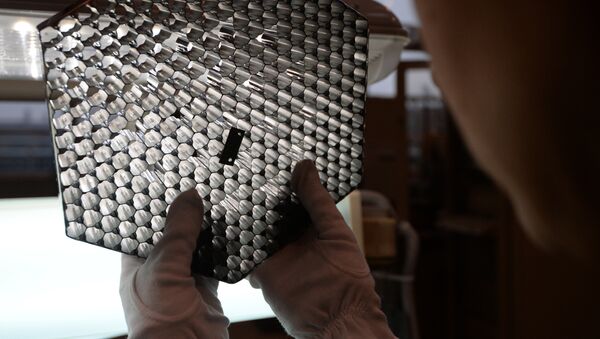

However, Russian scientists believe they may have found a solution, in the form of an isotopically modified molybdenum, created using centrifugal isotope separation technology, which allows for the creation of an alloy with thermal neutron capture cross-section figures similar to or even smaller than that of zirconium.

If introduced, the technology could lead to substantial increases in nuclear power plant safety.

The university's study, published in the peer-reviewed scientific journal Chemical Engineering Research & Design, was made possible thanks to support from the Russian Foundation for Basic Research, and in cooperation with the department of engineering physics at Tsinghua University in Beijing, China.