The results of the study were published in the Applied Surface Science journal.

The clinical need for artificial vessels (vascular grafts) is in high demand today for the treatment of acute deep vein thrombosis. If it is no longer possible to restore the functionality of the vessel medically or surgically, the affected area is removed and replaced with an artificial vessel made of polycaprolactone or another biocompatible material.

"The principal advantage of our grafts is that their outer surface is well wetted with water (hydrophilic), thus allowing them to easily take root in the body, while the inner surface, on the contrary, is not wetted (hydrophobic), thereby ensuring optimal blood flow", Evgeny Bolbasov, a research fellow at the TPU Plasma Hybrid Systems Laboratory, said.

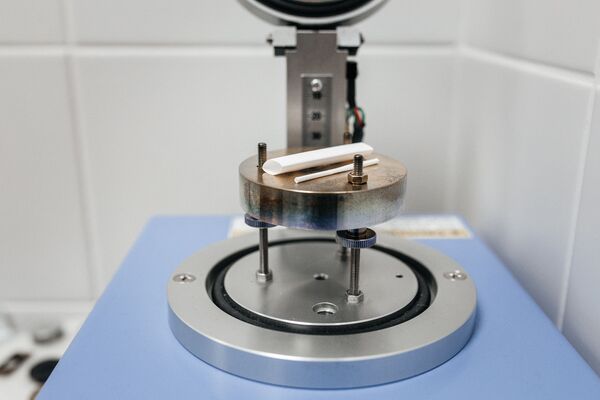

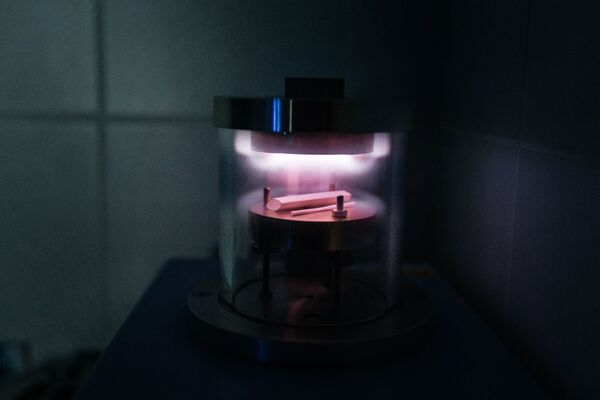

TPU scientists have for the first time suggested using the method of polycaprolactone processing in the plasma of magnetron discharges for the creation of artificial vessels.

According to the authors, it simultaneously provides two key characteristics of grafts: high-quality integration of the material with the patient's tissue and high tightness.

"The uniqueness of the new home-grown technology is that it is very simple and 90% cheaper than the existing methods of production of artificial vessels", Sergei Tverdokhlebov, head of the TPU Plasma Hybrid Systems Laboratory, added.

Today, extremely complex processing and expensive preparations are used to improve the survival rate of implanted grafts. However, scientists say that as a result, the mechanical and functional characteristics of such vessels still leave much to be desired. The authors noted that TPU's development is devoid of these shortcomings.

In the future, the research team, together with the specialists from the Cardiology Research Institute at the Tomsk National Research Medical Centre of the Russian Academy of Sciences, intends to proceed to test the medical and biological properties of the developed grafts on living tissue.