Defense manufacturer Lockheed Martin will be producing the parts. In a company release, Lockheed announced, "a Remote Interface Unit, an aluminum electronic enclosure designed to hold avionic circuits, will be the first 3-D printed part certified for use on a Lockheed Martin military satellite."

The change will speed up manufacturing and assembly, according to Lockheed. "The lead time for manufacturing the part went from six months to only 1.5 months, with assembly time also being reduced from 12 hours to just three hours," the company said.

Using a process called Laser Powder Bed Fusion additive manufacturing, the 3-D printed part is made based on a digital design. A laser is used to melt and fuse layers of aluminum metal powder to form the part.

Iris Bombelyn, vice president of Lockheed’s Protected Communications, said in an early April release that "3-D printing provides the ability to rapidly implement innovation by controlling production from design through implementation with one digital model … By providing affordable, innovative solutions for our customers with a reduced timeline, we are able to adjust to the rapidly changing environment of military space."

According to the company, using one 3-D printed part instead of multiple machined parts not only saves time on production and design, but increases the consistency and quality of the unit.

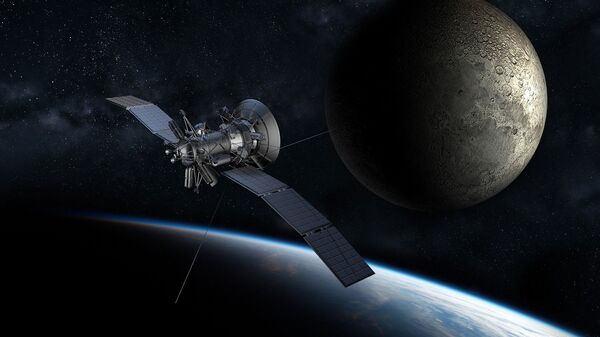

AEHF satellites are used to provide protected communication for tactical warfighters and strategic commanders. The global military satellite communications system will be delivered by Lockheed in 2017. The AEHF 5 and AEHF 6 are currently in production, with the AEHF 5 expected to launch in 2018 and the AEHF 6 in 2019.